Οur background

GOLDPRINT SA started its activity in the field of label-making in 1995 in Piraeus, specializing in the hot-impressing method.

Working with diligence and professionalism and relying on the trust and support of our associates, we managed to implement a well-designed development programme within a short period of time, focusing on technological infrastructure and the specialized human resources.

In the context of this programme, the GOLD PRINT facilities were moved in 2001 to Aspropyrgos. In the pre-press department, the specially trained personnel of our company, using the most specialized graphics programmes and the spearhead CTP technology in lithographic printing, secures the provision of high quality services for our customers.

Today, GOLD PRINT activities are housed in an area 1500m2 of high specifications with a plethora of hot-impression machines, LETTER PRESS cylinder machines, OFFSET and quality control machines. In order to secure the high level of the offered services, we take care to continuously modernize the technical infrastructure using the most advanced machines in the market and also to continuously train the company’s personnel offering specializations to always achieve the perfect result in the production of any type of labels.

Our aim has always been to apply “HIGH QUALITY – SERVICE – DIRECT COMMUNICATION” in combination with competitive prices. This aim has been served all these years, always adhering to and being consistent to our principles.

Your trust is our strength.

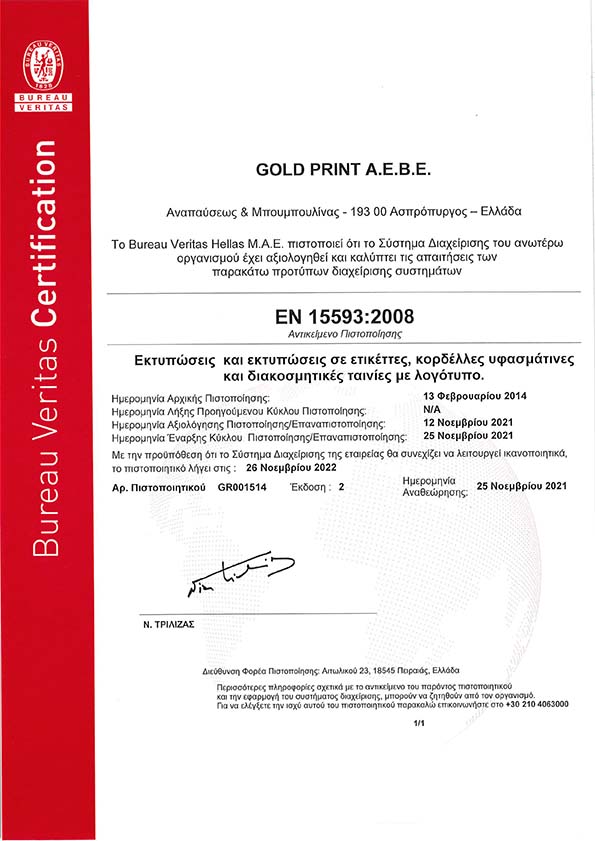

Certifications

The specifications and production procedure has always had strict criteria.

Being pioneers in the field, we were ISO: 9001 certified in 1999, in less than 2 months.

A significant percentage of the turnover of Goldprint belongs to the food field and this is why the company is in the process of acquiring HACCP certification.

SMETA 2 Pillar – Corporate Social Responsibility

Sedex is a not for profit, membership organization which is dedicated to driving improvements in ethical and responsible business practices in global supply chains. Sedex aims to achieve two important things: ease the burden on suppliers by reducing the need for numerous audits, questionnaires and certifications.

SMETA (Sedex Members Ethical Trading Audit) is an audit methodology, providing a compilation of best practice ethical audit techniques. It is designed to help auditors conduct high quality audits that encompass all aspects of responsible business practice, covering Sedex’s four pillars of Labour, Health and Safety, Environment and Business Ethics.

Equipment

Goldprint SA, having as a criterion the high quality of the produced products, the direct communication and the perfect service for its customers, has been fitted with the equipment of a vertical unit with spearhead technology machines

Goldprint SA, having as a criterion the high quality of the produced products, the direct communication and the perfect service for its customers, has been fitted with the equipment of a vertical unit with spearhead technology machines. The fleet of the mechanical equipment is automated and controlled by electronic systems.

The new OFFSET COMBINATION production line used for the production of labels makes it one of the most qualitative companies in the label-making field with high definition prints, even RASTER 1%, which is difficult in other technologies.

We offer 4-colour prints, PANTONE, silk screen printing, hot-impression printing, FLEXO, SPOT UV, even for simultaneous A and B face labels.

All the foregoing lead to competitive prices, and high, and mainly stable, quality of products.

It is not accidental that Goldprint is one of the most quality companies in the label-making field.

Facilities

Goldprint SA facilities are located at Aspropyrgos in a building of 1500m2.

The whole production and offices areas are air-conditioned achieving stable temperatures all year round.

In this way we offer good working conditions, perfect storage conditions of the raw materials and stable quality.

Personnel

Goldprint believes that a successful course is not only shown in numbers and financial indicators but mainly in the honesty and respect shown to the employees, customers and, consequently, to the society.

The Human Resources policy recognizes that its employees comprise the most significant capital of the company.

Goldprint, via a Code of Conduct, aims at the just and equal treatment of its employees, irrespective of race, gender, religion, languages etc.

Each employee of the Goldprint is entitled to be shown respect and honesty both by the other employees as well as the company’s associates and is offered equal opportunities of training and development.

The human resources of Goldprint have long experience in label production, with full knowledge of the today’s know-how and with open horizons for the future.

Organisation and Storage

The first care of Goldprint, as a production unit, was and still is organisaton.

We have invested in organisation both in electronic means as well as in specialized storage systems.

Safety

The safety of its personnel is Goldprint’s priority. It strictly adheres to all safety rules of the mechanical equipment and fire safety and we are proud of the fact that no work accident has occurred for a period of 5163 days.

Environment

We have entered into annual contracts with waste and recycle companies. The suppliers of our raw materials are companies with high specifications and distinguished all over the world.

All together for the protection of the Environment.

Mission and Vision

High and qualitative services for our associates – customers.

The specifications of our Raw Materials are the best possible solutions so that each label would become identical with the product. Goldprint’s team believes that the label is the window of the product.

LET’S STICK A QUALITY LABEL TOGETHER

REPRESENTING YOUR QUALITY PRODUCT.

Corporate vision

Our vision is to invest in the future, to provide high quality services, always showing respect to the human being and protection of the planet for a better tomorrow for the future generations.